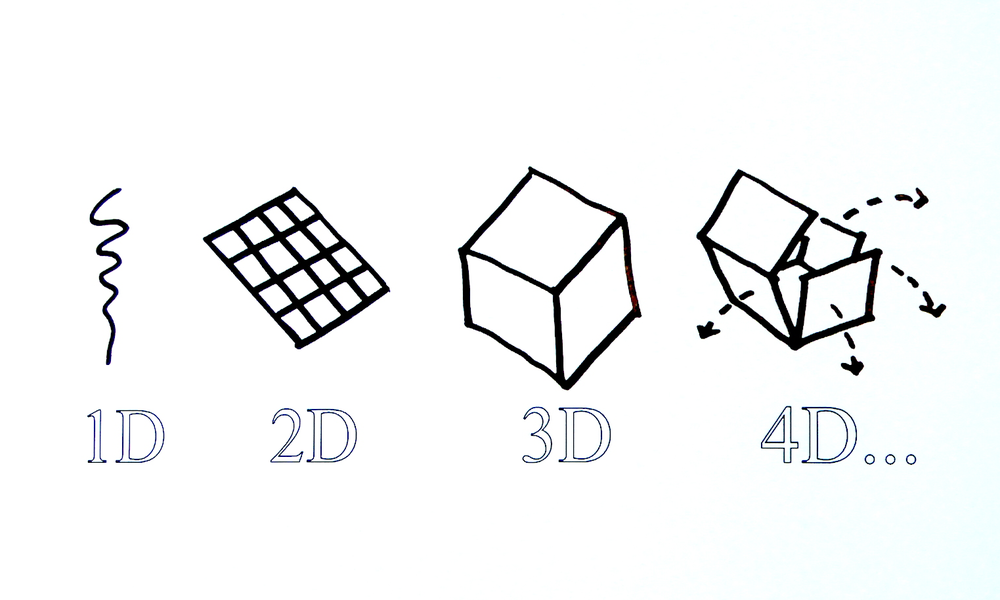

Inside the review, our prime focus is to highlight the enormous application and exploring the capabilities of 4D printing technology of additive manufacturing technology to achieve a better understanding of this technique. Significantly, AM technology proves its tremendous influence in the field of manufacturing of specified material such as layer to layer hybrid materials, functionally graded and multiple materials. The strategic applications of additive manufacturing include rapid tooling, rapid prototyping, and rapid manufacturing. 3D and 4D printing consumption are the basic way to make an example. ASTM internationally differentiated additive manufacturing technique into seven categories typical materials and their alternative names are given in Fig. 3D and 4D printing research start to be acknowledged in academic circles, and particularly, additive manufacturing is regarded to be one main trigger to change and evolve in defense sector in the twenty-first century. The three primary areas of additive manufacturing are university, industry, and government sectors, which all implement innovative strategies. Perhaps, the most recent headway leaves Northwestern University, where experts have built up an advanced 3D printer that is fit for printing a grown-up human-sized item in a couple of hours. Almost over 50 Chinese universities including Tsinghua University, Xian Jiao Tong University, HUST, and the South China University of Technology work on 3D and 4D printing. However, the strong interest was shown in 4D printing of the US Army, Europe, and Asia such as China.

Educational, innovation process followed 3D printing throughout states an extensive review. This approach has become the advance of learning classes through experiments and awareness on additive manufacturing information. Martin Stevens, CEO of IT IS 3D company overview, the technology can’t be successively enhanced but also the workforce of the future. Innovative framework for AM technology 3D printing implications for STEM (Science, Technology, Engineering, and Mathematics-related topics) education in the first decade of the 21 century.

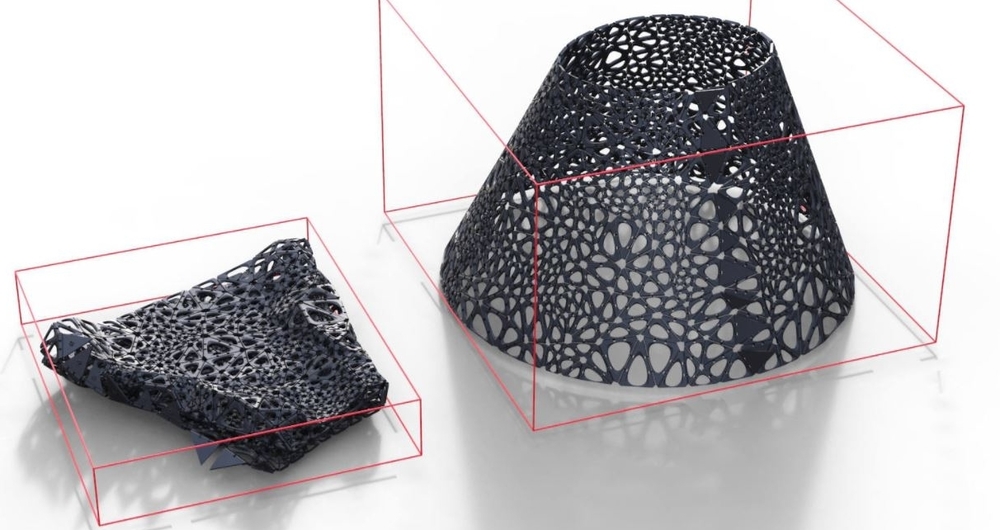

Additive manufacturing is widely used in aviation organizational relationships and procedures between enterprises. Additive manufacturing first patent was formally designated by ASTM “American Society for Testing Materials” for an extensive range of materials, systems, and corresponding products. Graphical abstractģD printing or additive manufacturing technology is indenting to transform the manufacturing world due to its potential to create any shape, size and geometry. We determined our review by aiming our future directions such as the “dream it and make it feasible” technology. Finally, we explored the future application potential under succeeding context: SMA-based knitted garments, transforming food, and relevant sectors wise development and proceedings with the advancement in smart materials. Furthermore, the capabilities of single and multiple materials mechanisms for shape-shifting behavior are summarized.

Starting from a generalized idea, and fundamental workflow, together with a graphical manifestation of the 4D printing concept, and 4D printing for shape-memory materials (SMMs), self-fitting wearables based on shape memory alloys (SMAs) are reviewed exclusively. Herein, the proposed review article discusses material arrangements for 4D printing, highlighting the structural evolvement mechanism, the behavior of deformation, and their prospective implementation with respect.

Although significant progress on smart material performance has been made and different studies have focused on new strategies and process improvements in typical additive manufacturing. 4D printing is inspired by embedded product designs to produce stimuli-responsive consumables fabricated by available commercial 3D printers.

0 kommentar(er)

0 kommentar(er)